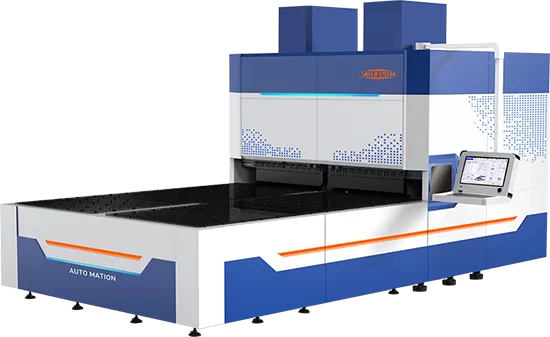

The panel bender focuses on solving various complicated sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is resolved from a technical perspective, which effectively improves production efficiency and reduces production costs.

PARAMETER

The panel bender focuses on solving various complicated sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is resolved from a technical perspective, which effectively improves production efficiency and reduces production costs.

DESCRIPTION

| Name | Supplier/Brand |

| Control system | Taiwan SYNTEC |

| Servo motor, drive | Taiwan SYNTEC |

| Cast body | AHXISIM Self-Developed |

| Welded body | AHXISIM Self-Developed |

| Feeding rack | AHXISIM Self-Developed |

| Reducer | Germany NEWGEAR |

| Screw rod | Taiwan HIWIN |

| Guide rail | Taiwan HIWIN |

| Bearing | Japan NACHI |

| Negative pressure pump | Zhejiang Tengyuan (Press arm type excluded) |

| Electrical parts | France Schneider |

| Grating ruler | Suzhou SINO |

| Hand wheel | Taiwan SYNTEC |

| Machine air conditioning | Tongfei Refrigeration |

| Pneumatic accessories | Taiwan AirTAC |

| Suction cup | AIRBEST (Press arm type excluded) |

| Coupling | Miki Pulley |

| Lubrication system | Guangdong Dingshen |

| Max. bending length (cm) | 320*150 |

| Max. bending height (mm) | 170/210 |

| Min. bending thickness (mm) | 0.15 |

| Min. four-sided forming size | 200*280mm |

| Single-sided forming | 150mm |

| Max. bending thickness (mm) | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 |

Product Features

Multiple bending shapes

Compatible with multiple sizes of sheet sizes

By simply assembling cutting tools, bending of workpieces of different sizes can be achieved;

Stainless steel sheet Aluminum sheet Cold rolled sheet

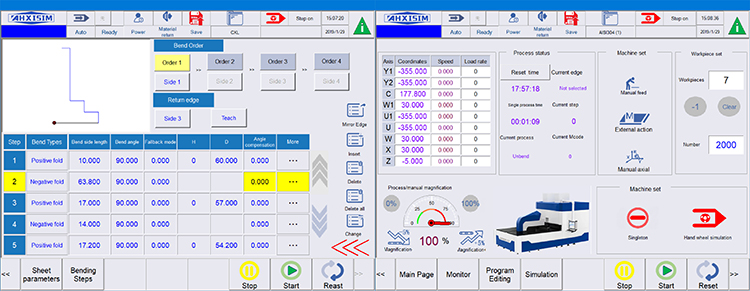

Graphical programming is easy to learn

Through graphic programming. By combining simple bending movements, various bending shapes can be achieved. Ordinary workers can learn in 2 hours.

Fast Bending Speed

The fastest bending speed is 0.2 seconds/time

The cutting speed, rotation speed, and bending speed can be adjusted; The fastest bending speed can reach 0.2 seconds per knife.

Continuous edge bending reduces bending cycle time

The system provides automatic posi- tioning function for sheet metal, using a-CNC positioning device for automat- ic positioning, completing multilateral bending in one positioning, and short- ening the bending cycle time.

Dual C-axis Automatic Follow System

Dual C-axis oblique borrowing mode

For special structural workpieces, such as water tank structures, the bending process of the workpiece can be achieved through automatic dual C-axis oblique borrowing.

Dual C-axis automatic follow

When the upper and lower jaws press the sheet metal, the lower C-axis rotates with the workpiece, and the upper C-axis auto- matically follows the lower C-axis to achieve synchronization and tightly grasp the workpiece.

Compatible Loading And Unloading Modes

Multiple loading and unloading modes available

Manual loading and unloading

Self driving integrated robotic arm loading and unloading

Single arm robotic arm+quilting frame loading and-unloading

Single arm robotic arm load- ing and unloading

Stable Performance And Long Life

Standard design of high precision machine tools

High grade castings (QT500-7 and gray iron 250). With high standard ful welding process. strlict stress relief treatment, precision machining, and high-precision assembly.

Strict testing and selection of components

The components used in the assembly of the entire machine have undergone strlict selection, rigorous testing, and long-term baking. The key components have undergone three years of matching and replacement.

More stable production performance

The first generation model has been tested and pro- duced for over three years. and its performance is stable and widely praised, Subse- quent models wil be upgrad- ed and iterated on this basis, with more complete functions and performance.

Safety Self Test Function

Folding front self inspection system

The system provides graphical visualization error detection programming, and can simulate the bending of the workpiece before bending. If the parameter settings are abnormal, the system will terminate the user's bending operation. Users can adjust the corresponding bending parameters according to the error content prompted by the system, effectively preventing the occurrence of incorrect bending.

Plate thickness detection system

The system provides a plate thickness detection system. When the workpiece enters the pressure zone, the workpiece thickness will be detected in real-time during the pressing process of the pressure knife. When the actual thickness of the detected workpiece is inconsistent with the program thickness,the system will immediately terminate the bending and prompt the user. The user does not need to worry about taking the wrong workpiece and damaging the.workpiece.

Partial load protection system

The bias load protection system of the pressing module will immediately respond to terminate bending and notify the user when the user accidentally places the workpiece in the wrong position of the pressing tool, or if the workpiece is non-standard (especially severe burrs, ete.). which will seriously affect the inconsistency of the pressing tool dual drive.

Partial load bending system

The system provides partial load bending function, which can still bend the workpiece normally when it is not in the center. The remote motor module can automatically follow, which can achieve more complex workpiece bending. Users do not need to worry about equipment damage or damage caused by this.

Collision protection system

The system provides collision protection function for each axis, so users do not need to worry about i nternal collision of the bending machine during the bending process, which may cause equip- ment damage or abnormalities. The system wil predict whether there will be interference at the position where each axis travels. If there is interferençe, it will immediately terminate and prompt the user.

Fuel supply detection system

The system provides automatic oil supply system and oil tank shortage detection prompt function. When the equipment has abnormal oil supply or oil shortage, the system will automatically alert. Users do not need to worry about core components such as equip- ment motors, bearings, and screw rods being damaged or affecting their service life due to a lack of oil lubrication.

Application Scenario

The file cabinet

Electrical cabinet

Kitchenware

Furniture

Decoration

2024 Canton Fair

At the 136th Canton Fair in 2024, AHXISIM showcased the most advanced fully automated bending center to visitors from all over the world, providing sheet metal bending solutions to partners on site, attracting the attention and attention of a large number of attendees, allowing supporters to personally experience how AHXISIM helps production enterprises improve efficiency and productivity.

Shipping And Packing

AHXISIM guarantees the delivery of each customer, with the panel bender equipment produced and tested for 40 hours of operation. The packaging is meticulous, with soft film wrapping, corner reinforcement, aerial crane handling, and steel cable fixation inside the container, ensuring that each device is delivered to customers completely and perfectly.

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 19955505001

Email: info@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY