Providing relevant technical support in accordance with customer requirements

Assist customers in the design and production of sheet metal bending solutions, considering technical feasibility. Providing customers with equipment demonstrations, making samples and testing, etc.

How do I choose a panel bender?

A.According to your own requirements - the right one is the best

You need to choose the most suitable machine for your own requirements; you need to consider the material you are bending, the size of the table; and most importantly, leave room for your future use.

B. According to your own budget - a cost-efficient machine

The relatively high price of panel benders compared to conventional machining equipment is the reason why many customers hesitate. However, automated bending technology is a much more sophisticated and advanced technology. It improves bending quality, processing speed and efficiency, reduces processing costs and saves on labour costs. In short, it is a worthwhile investment.

What we offer

In addition to offering tailor-made and timely solutions to maximise the production potential of AHXISIM panel benders, we can also provide door-to-door service, maintaining an extensive global coverage.

Software supply

We develop tailor-made, linked full servo CNC systems designed to continuously improve the performance of your machine. Customised interfaces are open and can be perfectly adapted to specific production requirements.

The software is updated in time to keep the machine's potential up to date and to facilitate start-up, programming and operation.

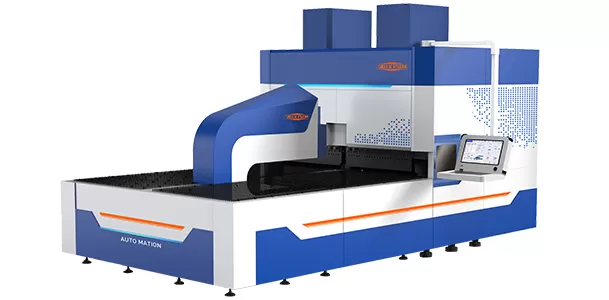

Machine supply

Products are built to support your ever-changing production needs. We continuously design specific machine supplies for each product line to meet your growing needs, optimise productivity and maximise your production flexibility to reduce production times for complex or completely different workpieces, even when produced in different modes.

Hardware availability

We can update your machine's control unit with new models compatible with the latest operating software. It is important to take advantage of these updates, such as the one that safely shuts down the system without interrupting production in the event of a power failure. This update is intended to protect all data running in real time. We recommend regular updates to the network to improve performance and keep the control system up to date. We also offer a special "rescue" solution that allows you to quickly restart production and manage faults offline.

Maintenance and evaluation

As indicated in the maintenance manual for each type of machine, we also offer a machine assessment to perform an evaluation of the current state of the machine and recommend repair measures to address any problems reported by technicians during the assessment.

Spare parts

The products are supplied from the factory with the spare parts most often required and with specially tailored spare parts kits that you can store on your premises and use as required.

Programming, maintenance and user courses

We offer practical training programmes in planning, maintenance and product use to enable you to make full use of the potential of AHXISIM panel benders and systems. Constantly improving and updating our courses, we are trained to provide you with the latest theoretical and practical guidance. In addition to our standard courses, we also offer individual training courses tailored to your specific requirements.

For more than 10 years we have been offering innovative technologies for flexible automation solutions to transform sheet metal into a range of different everyday products.

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 19955505001

Email: info@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY