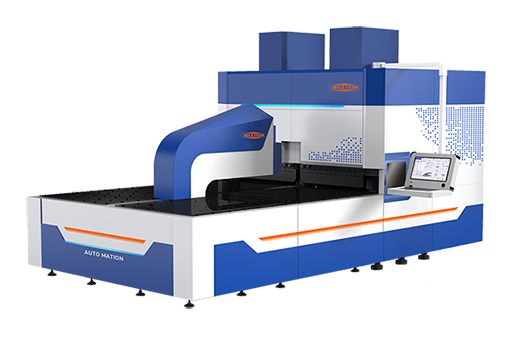

Panel benders are at the forefront of modern sheet metal fabrication, combining advanced technology with enhanced safety features to create a secure working environment. As industries increasingly prioritize worker safety alongside productivity, panel benders have evolved to incorporate numerous safety mechanisms that protect operators from potential hazards during the bending process.

These machines are designed with automated systems that minimize manual handling, significantly reducing the risk of accidents caused by human error. Features such as emergency stop buttons, light curtains, and interlocks ensure that operators can work confidently, knowing that safety protocols are in place. Additionally, the intuitive control systems allow for easy programming and monitoring of operations, further enhancing user safety by providing real-time feedback on machine status.

The integration of advanced safety features not only protects personnel but also contributes to the overall efficiency of the manufacturing process. By reducing the likelihood of accidents and downtime, businesses can maintain high production levels while fostering a culture of safety within their operations. As a result, investing in a panel bender equipped with cutting-edge safety technology is a strategic choice for manufacturers looking to enhance both productivity and workplace safety.