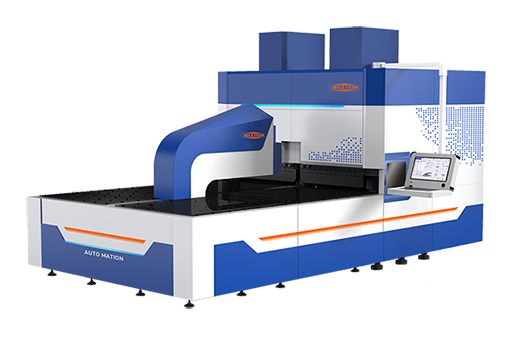

How Does Electric Panel Bender Machine With Energy Efficiency Work? The electric panel bender machine is a state-of-the-art device used in bending sheet metals of different thicknesses to achieve custom sizes, shapes, and designs. One significant advantage of this technology is its energy efficiency. The machine is designed to operate at a lower power consumption than traditional panel benders, and this translates to cost savings for the user. Key Components The electric panel bender machine is fitted with various key components that work together to achieve efficient bending of metals. These include a steel frame, motors, a control unit, a feed system, and a bending unit. The control unit is the machine's brain where the operator can input the bending parameters such as the angle, radius, and dimensions. Working Mechanisms The machine works by clamping the sheet metal securely onto the bender's end and feeding it through the device's feed rollers. The rollers pull the metal through the bending unit, where it is shaped to the desired angle or design. The motors driving the feed rollers and bending units are powered by electricity, reducing the amount of energy needed to operate the machine. The machine can work in different directions, allowing for flexibility in bending metals. Advanced Technology and Efficiency The electric panel bender machine leverages advanced technology to enable efficient production processes, including energy-efficient power consumption. The machine is designed to reduce operating costs while maintaining high production efficiency. This technology is highly beneficial in modern manufacturing, where companies need to operate sustainably and focus on energy-efficient technologies to meet the growing demand for eco-friendly production processes. Practical Examples Suppose a metal fabrication company requires a custom designed sheet metal for an architectural project. In that case, the electric panel bender machine with energy efficiency technology can be used to produce the required sheet metal at a lower cost than traditional panel benders. This technology also comes in handy for mass producing products where time and energy conservation are critical elements. Conclusion In conclusion, the electric panel bender machine with energy efficiency technology is a game-changing innovation in metal fabrication processes. Its energy-efficient power consumption and advanced technology enable efficient production processes that are cost-effective, eco-friendly, and sustainable. Contact us to learn more about this technology and how to acquire it from leading suppliers.