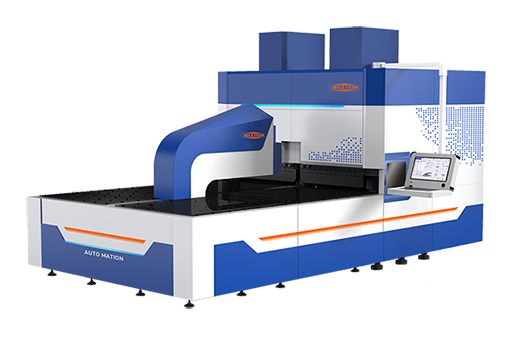

Panel benders are essential tools in the metal fabrication industry, designed to meet the demands of high-volume production while ensuring durability and reliability for frequent use. These machines excel in bending metal sheets into precise shapes, making them invaluable for manufacturers who require consistent performance over extended periods. Built with robust materials and advanced engineering, modern panel benders can withstand the rigors of continuous operation, reducing downtime and maintenance costs.

The durability of panel benders is complemented by their automation capabilities, which streamline the bending process and minimize the need for skilled labor. This combination allows operators to achieve high levels of efficiency without sacrificing quality. With features such as quick tool changeovers and user-friendly interfaces, panel benders are designed for ease of use, enabling even less experienced operators to produce high-quality bends consistently.

In industries where production speed and accuracy are critical, the durability of a panel bender ensures that it can handle frequent use without compromising its performance. As manufacturers continue to seek solutions that enhance productivity while maintaining operational integrity, durable panel benders stand out as a reliable investment for long-term success in metal fabrication.