Panel benders have become indispensable in the realm of sheet metal fabrication, offering a blend of efficiency, precision, and versatility that traditional bending methods struggle to match. As manufacturers seek to streamline their operations and enhance productivity, selecting the best panel bender is crucial for optimizing workflow and achieving high-quality results.

Modern panel benders are engineered to handle a variety of materials, including aluminum, stainless steel, and mild steel, accommodating different thicknesses and bending angles. Their automated features significantly reduce setup time and labor costs while ensuring consistent performance across numerous bending cycles. This makes them ideal for industries ranging from automotive to construction, where high-volume production is often required.

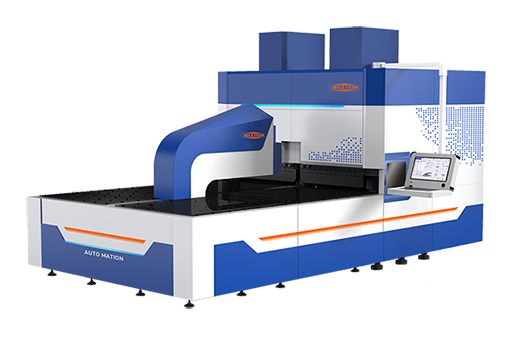

Among the leading models available today, options such as fully automated high-speed panel benders stand out due to their rapid processing capabilities and advanced technology. These machines not only improve production efficiency but also allow for complex bending tasks that enhance design flexibility. By integrating sophisticated control systems, they ensure precise bends with minimal operator intervention, making them a smart investment for any sheet metal fabrication operation.

In conclusion, investing in the best panel bender tailored to specific production needs can lead to significant improvements in manufacturing efficiency and product quality, positioning businesses to thrive in a competitive market.