A panel bender is a specialized machine used in the production of appliance doors, particularly for bending and shaping metal panels. This equipment is designed to efficiently and accurately bend metal sheets or panels, creating the desired shape for appliance doors. The bending process is crucial in forming the structural and aesthetic components of the doors.

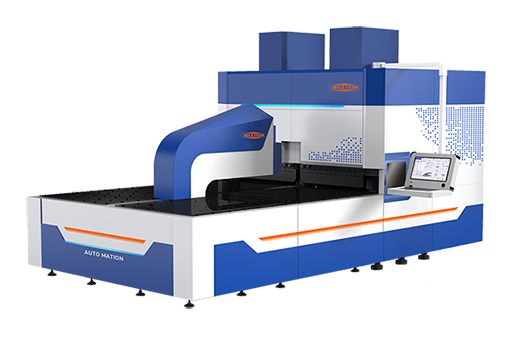

Panel benders are equipped with various features and tools to handle different types of metal and achieve precise bends. These machines often have computer numerical control (CNC) capabilities, allowing for programmable and automated bending processes. CNC panel benders can be programmed to produce consistent and complex bends, ensuring uniformity in the manufacturing of appliance doors.

In the manufacturing of home and commercial appliances, the quality and precision of appliance doors play a crucial role in both functionality and design. A Panel Bender, specifically designed as an Appliance Doors Bending Machine, is an essential tool for creating precise bends in the sheet metal used for appliance doors, such as those found on refrigerators, ovens, and washing machines.

This specialized machine ensures that the metal panels used for appliance doors are shaped with accuracy, providing consistent bends that meet high-quality standards. Its ability to handle various materials, including stainless steel and aluminum, allows manufacturers to produce durable, well-fitted doors that are both aesthetically pleasing and reliable.

With automated features, the Appliance Doors Bending Machine increases production efficiency, reduces material waste, and minimizes labor costs. This technology enables appliance manufacturers to achieve faster production times while maintaining the precision and durability that modern consumers expect from their appliances.