Press brake forming is an efficient and versatile method of forming sheet metal. The process utilizes the force of hydraulic cylinders to apply pressure and bend the material into the desired shape. With precise controls and adjustable settings, hydraulic press brakes forming offers superior accuracy and repeatability, making it ideal for a variety of industries including automotive, aerospace and construction. Whether it's creating crisp angles, complex curves or straight bends, hydraulic press brake forming provides the flexibility and precision needed for a variety of metal fabrication projects. With advanced technology and innovative features, hydraulic press brake forming enables manufacturers to realize complex designs, meet tight tolerances and produce high-quality finished products.

PARAMETER

Oil Electric Hybrid Drive Press Brake

Main Technical Parameters

| Specification parameters (T/MM) | XSM 50/1500 | XSM 80/2500 | XSM 110/3200 | XSM 130-400/3200 XSM 110-320/4000 |

| Nominal pressure | 500KN | 800KN | 1100KN | |

| Workbench length | 1500mm | 2500mm | 3200mm | |

| Column spacing | 1200mm | 2100mm | 2700mm | |

| Slide stroke | 165mm | 165mm | 205mm | |

| Maximum opening | 420mm | 420mm | 460mm | |

| height | ||||

| Throat depth | 250mm | 250mm | 400mm | |

| Workbench height | 850mm | 930mm | 930mm | |

| Quick down speed | 250mm/s | 230mm/s | 220mm/s | |

| Slow down speed | 10mm/s | 10mm/s | 10mm/s | |

| Return speed | 200mm/s | 180mm/s | 160mm/s | |

| Main motor power | 5.5kw | 7.5kw | 7.5kw | Welcome to consult online and publish a complete parameter table for you |

| Fuel tank volume | 180L | 280L | 300L | |

| (liters) | ||||

| Rear stopper X-axis travel | 600mm | 600mm | 600mm | |

| Overall dimensions(length * width *height) | 1750*1350*2200mm | 2800*1400*2500mm | 3550*1650*2600mm | |

| Machine weight | 3.7T | 5.8T | 7.8T |

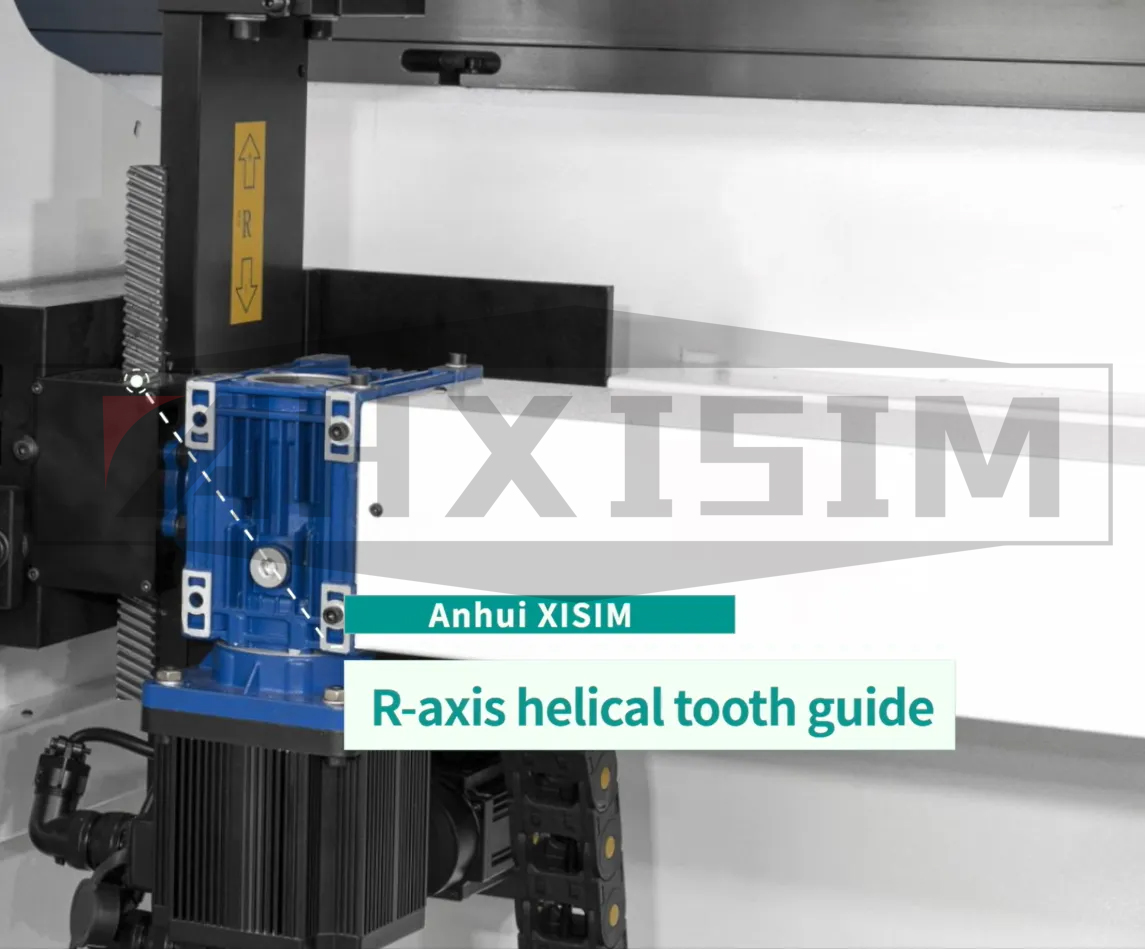

R-axis helical tooth guide

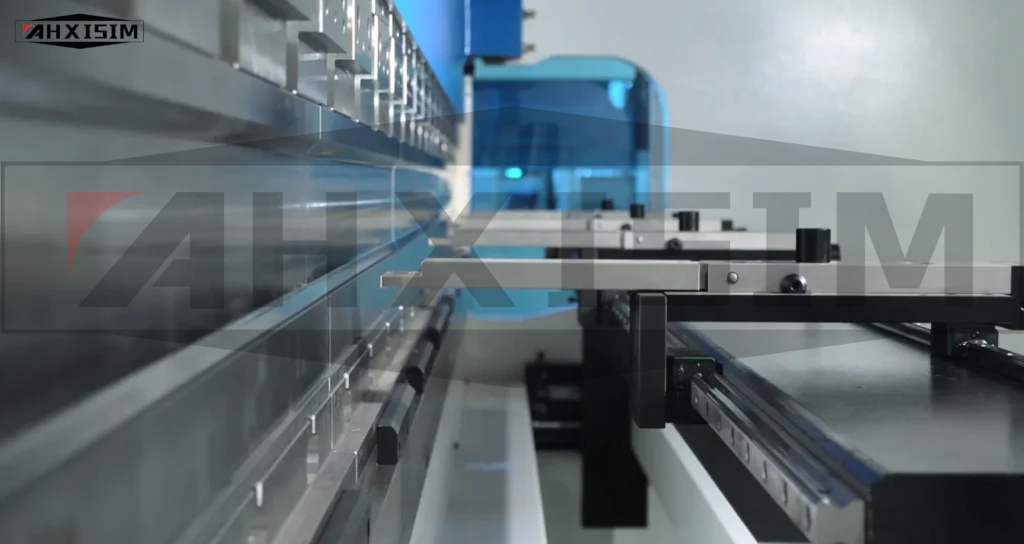

Back gauge X-axis

Crowning Table

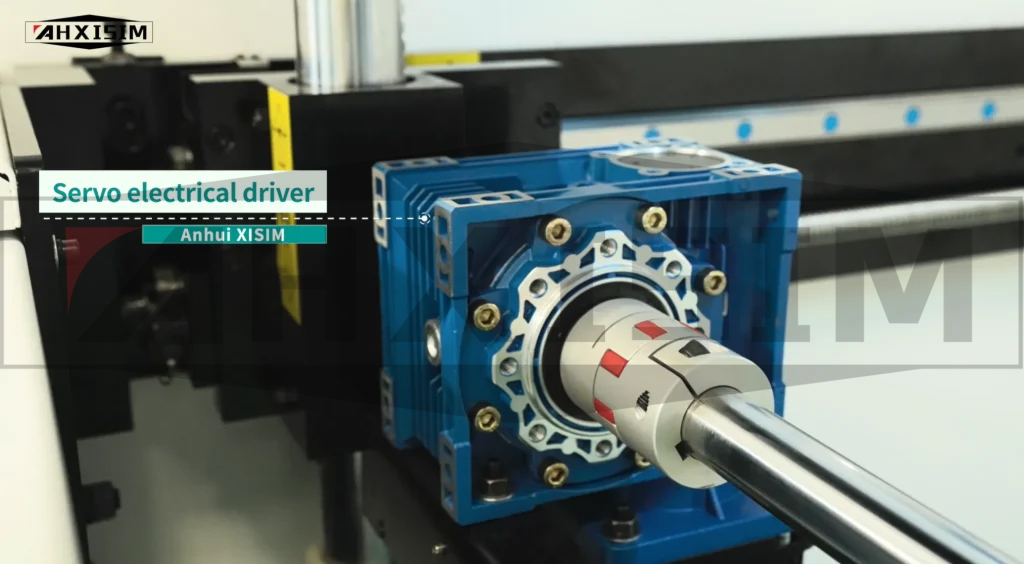

Servo electrical driver

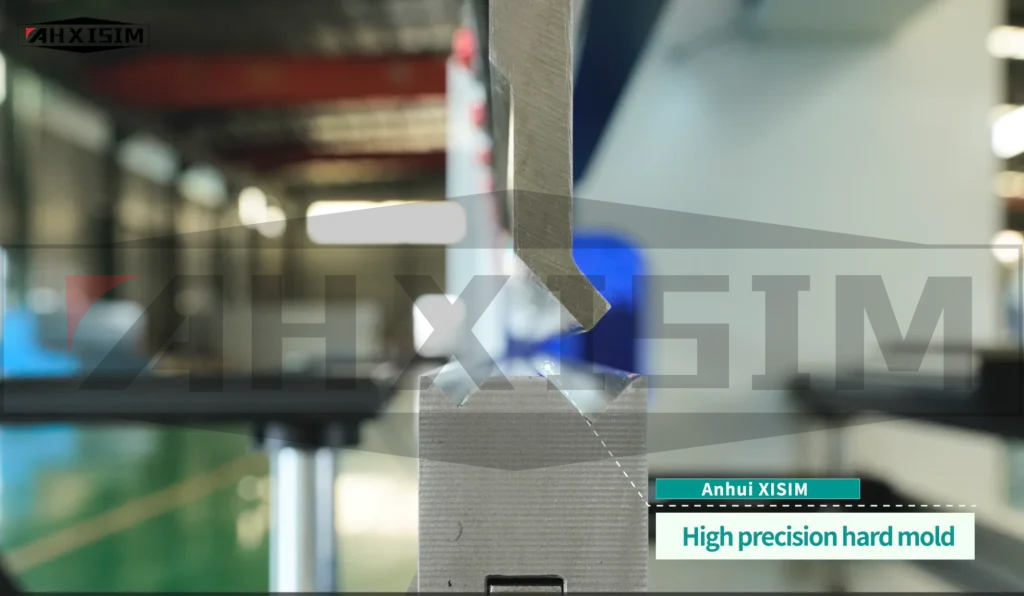

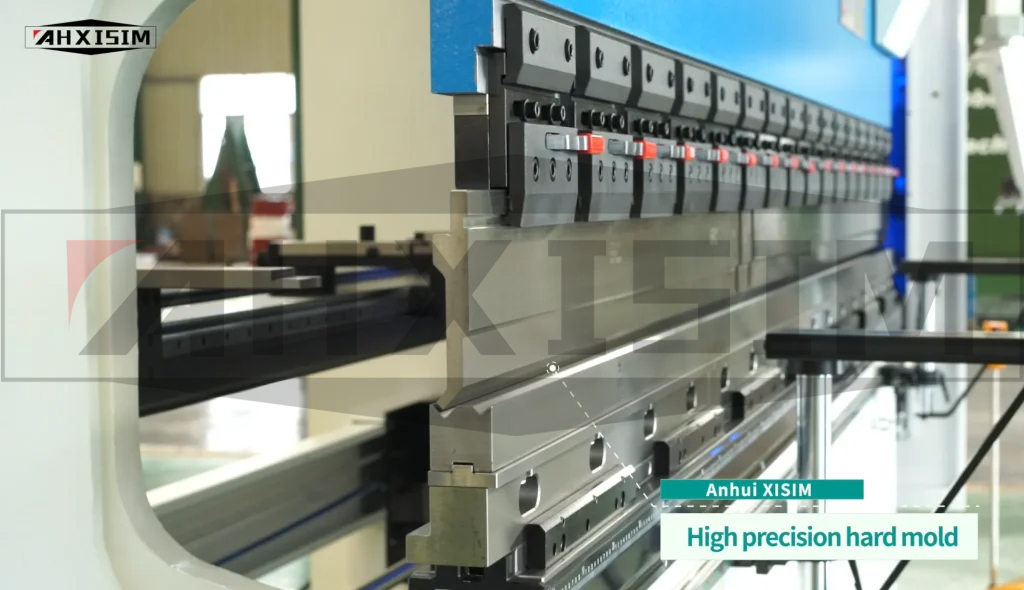

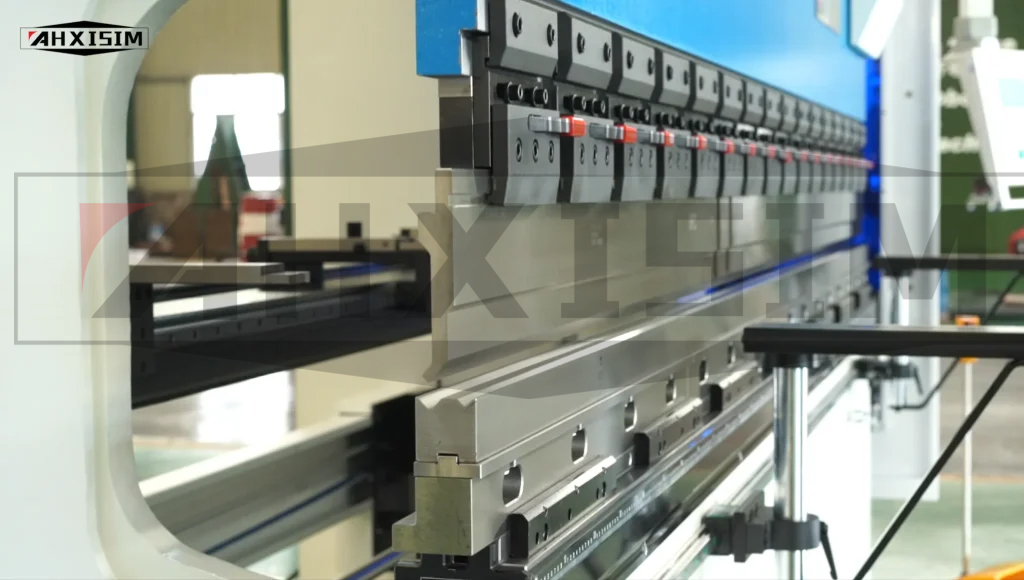

High precision hard mold

Ball screw and linear guide

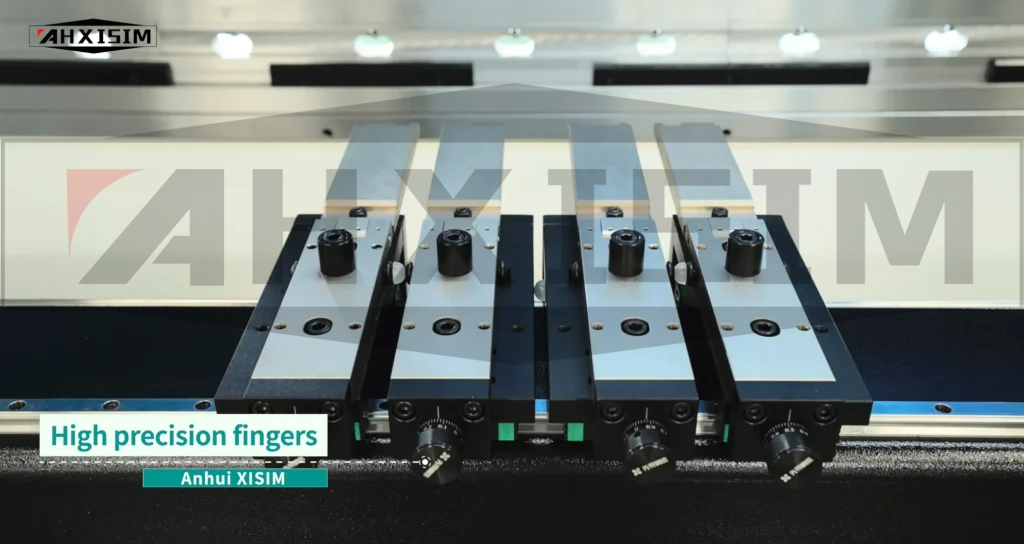

Backstop finger

Related Products

Single Cylinder Series 120KN 600mm Full Electric Press Brake

Single Cylinder Series 120KN 600mm Full Electric Press Brake

Hydraulic CNC Sheet Metal Press Brake

Hydraulic CNC Sheet Metal Press Brake

AHXISIM 6+1 Axis DA66T CNC Press Brake

AHXISIM 6+1 Axis DA66T CNC Press Brake

Double Cylinder Series 120KN 600mm Full Electric Press Brake

Double Cylinder Series 120KN 600mm Full Electric Press Brake

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 19955505001

Email: info@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY