The NC press brake connects the left and right swing arms through the torsion axis to form a torsion axis forced synchronization mechanism, so that the oil cylinders on both sides can move up and down, thereby realizing the synchronous movement of the slider. The NC press brake has been widely used in the metal processing industry for its advantages such as high precision, stability, high degree of automation and cost-effectiveness.

NC Press Brake

An NC Press Brake (Numerical Control Press Brake) is a type of machine tool used in metal fabrication to bend and shape sheet metal with high precision.

Numerical Control System: The NC system uses numerical input to control the back gauge (the mechanical stop for positioning the metal), which sets the distance for each bend. Operators manually set each step of the bending process.

Adjustable Ram Movement: The ram (the moving part that presses down on the metal) is controlled by the NC system, ensuring consistent bending force and angle.

Manual Programming: Operators input each command into the NC controller, usually through a keypad or a similar interface, allowing for adjustments based on the thickness and type of material being processed.

Limited Automation: While NC Press Brakes automate some parts of the process, they require manual setup and adjustments for each operation, unlike CNC (Computer Numerical Control) Press Brakes, which are fully automated.

Cost-Effective: They are generally more affordable than CNC Press Brakes, making them suitable for small to medium-sized manufacturing facilities.

Precision: They provide accurate bending, especially for simpler tasks, and are ideal for straightforward or medium-complexity metal bending jobs.

User Control: Since operators manually set parameters, NC Press Brakes allow for a high degree of customization and flexibility.

| Machine tool type | Nominal pressure (KN) | Table length (mm) | Throat depth (mm) | Column spacing (mm) | Slide travel (mm) | Maximum opening height (mm) | Main motor power (KW) |

| 63T/2500MM | 630KN | 2500MM | 280 | 2050 | 120 | 350 | 5.5 |

| 80T/2500MM | 800KN | 2500MM | 320 | 2050 | 120 | 370 | 7.5 |

| 100T/2500MM | 1000KN | 2500MM | 400 | 2050 | 120 | 370 | 7.5 |

| 125T/2500MM | 1250KN | 2500MM | 400 | 2050 | 140 | 40 | 7.5 |

| 100T/3200MM | 1000KN | 3200MM | 400 | 2560 | 120 | 370 | 7.5 |

| 125T/3200MM | 1250KN | 3200MM | 400 | 2560 | 140 | 370 | 7.5 |

| 160T/3200MM | 1600KN | 3200MM | 400 | 2550 | 180 | 460 | 11 |

| 200T/3200MM | 2000KN | 3200MM | 400 | 2500 | 200 | 470 | 11 |

| 250T/3200MM | 2500KN | 3200MM | 400 | 2500 | 250 | 550 | 18.5 |

| 300T/3200MM | 3000KN | 3200MM | 400 | 2500 | 250 | 560 | 22 |

| 100T/4000MM | 1000KN | 4000MM | 400 | 3160 | 120 | 370 | 7.5 |

| 125T/4000MM | 1250KN | 4000MM | 400 | 3150 | 140 | 370 | 7.5 |

| 160T/4000MM | 1600KN | 4000MM | 400 | 3150 | 180 | 460 | 11 |

| 200t/4000MM | 2000KN | 4000MM | 400 | 3100 | 200 | 470 | 11 |

| 250T/4000MM | 2500KN | 4000MM | 400 | 3100 | 250 | 550 | 18.5 |

| 300T/4000MM | 3000KN | 4000MM | 400 | 3100 | 250 | 560 | 22 |

| 400T/4000MM | 4000KN | 4000MM | 400 | 3100 | 300 | 600 | 30 |

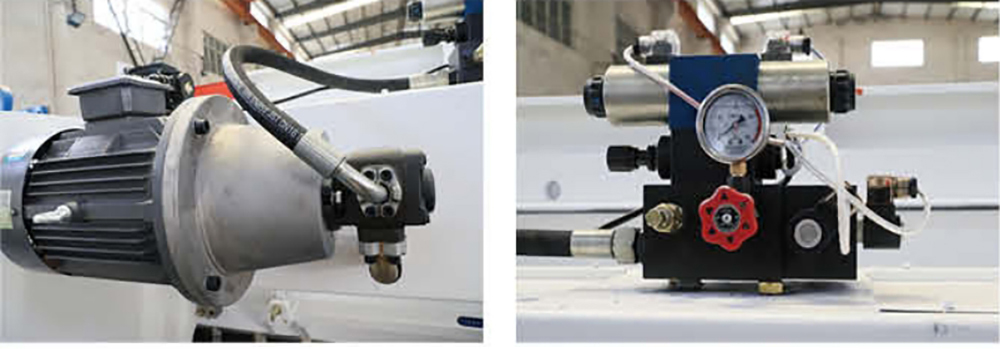

Plunger Pumpa Hydraulic System

Servo Motor Rear Gear Ball Screw, Linear Guide Rail

Quick Clip Standard CNC Mold Slide Stroke Switch

Hinge Structure Electrical Cabinet

| TP10S 10 inch high-definition TFT 256K true color touch screen Standard Y and X1 axis servo motors Support angle programming, the system automatically calculates the bending depth of the sheet metal Position control of slider (Y-axis) Position control of rear stopper (X1 axis) 220 programs, each program has 24 steps Soft limit function, power-off memory Optional support for X2, R1, R2, Z1, Z2 Optional support for tolerance compensation |

| E300 Automatic calculation of gear block position High precision control of rear blocking material Angle programming and position programming Support parameter backup and recovery, import and export Pressure holding time and concession waiting can be directly controlled Unidirectional and bidirectional positioning functions Refusal and material evasion function Metric and English and Chinese English |

| DA-41S Using servo control technology 4.7 "High brightness LCD display screen Multiple language interfaces including Chinese Mold parameter settings, bending angle programming Can store 100 programs with 25 steps per program Programmable material selection and counting of processing quantities Power outage memory, metric/imperial conversion |

Related Products

Single Cylinder Series 120KN 600mm Full Electric Press Brake

Single Cylinder Series 120KN 600mm Full Electric Press Brake

Double Cylinder Series 120KN 600mm Full Electric Press Brake

Double Cylinder Series 120KN 600mm Full Electric Press Brake

Hydraulic CNC Sheet Metal Press Brake

Hydraulic CNC Sheet Metal Press Brake

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 19955505001

Email: info@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY