Hydraulic bending machine forming is an efficient and versatile method of forming sheet metal. The process utilizes the force of hydraulic cylinders to apply pressure and bend the material into the desired shape. With precise controls and adjustable settings, hydraulic press brakes forming offers superior accuracy and repeatability, making it ideal for a variety of industries including automotive, aerospace and construction. Whether it's creating crisp angles, complex curves or straight bends, hydraulic press brake forming provides the flexibility and precision needed for a variety of metal fabrication projects. With advanced technology and innovative features, hydraulic press brake forming enables manufacturers to realize complex designs, meet tight tolerances and produce high-quality finished products.

CNC Hydraulic Sheet Metal Press Brake

The press brake is a machine that can bend thin plates. Its structure mainly includes a bracket, a workbench, and a clamping plate. The workbench is placed on the bracket, and the workbench is composed of a base and a pressing plate. The base is connected to the clamping plate through a hinge. The base is composed of a seat shell, a coil, and a cover plate. The coil is placed inside the depression of the seat shell, and the top of the depression is covered with a cover plate. When in use, the coil is energized by a wire, which generates a gravitational force on the pressure plate, thereby achieving the clamping of the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressure plate can be made into various workpiece requirements, and can be processed on workpieces with side walls, making the operation very simple.

| Energy Saving And Efficientservo Pump Controlled Cnc Press Brake Servo pump controlled drive, significant energy-saving effect, optional mechanical deflection compensation, higher precision in sheet metal processing High speed rear blocking matched with high-speed hydraulic system, with higher overal eficiency, precise blocking finger, and expandable blocking range, suitable for processing ultra wide sheet metal Friendly human-machine operation interface, 2D programming |

Unidirectional Servo Pump Control Technology The oil pump motor uses a servo motor as the main motor to achieve real-time control of motor speed, reduce unnecessary work done by the oil pump, and achieve energy-saving, efficient, and stable characteristics of the bending machine. The most cost-effective energy-saving hydraulic bending control technology |  |

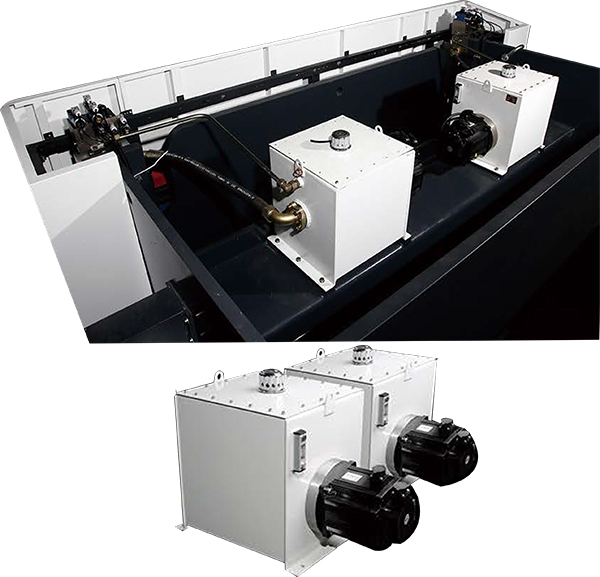

| Bidirectional Servo Pump Controlled CNC Bending Machine The hybrid oil electric drive bending machine is currently the latest top-level technology in domestic bending machines. Compared to the electric wave synchronous bending machine, its wave pressure synchronization work relies on high-power dual servo pumps to complete, without relying on throttle valves to control the oil cylinder. During operation, the hydraulic oil temperature will not rise, achieving the goal of extending the working life of the hydraulic system. So this model has all the advantages of electro-hydraulic synchronization, as well as the characteristics of high efficiency, energy saving, silence, and durability. Hydraulic servo pump imported from Germany Efficient and energy-saving, reducing fuel tank capacity by 70% Fast - performance improvement, reduced work cycle by 10% Compared to traditional systems, energy efficiency increases by 50% Precision - up to 5 μ m positioning accuracy Integrated servo pump system, lower noise during operation Integrated pressure wave filter ensures high stability and long service life |

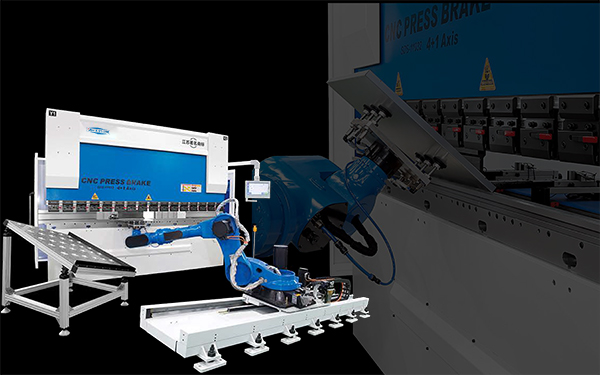

CNC Press Brake+Bending Manipulator We designed a heavy load sheet metal bending manipulator, realize the follow-up action of the bending process, and appropriately reduce the manufacturing cost of products, Improving the competitiveness of enterprises |  |

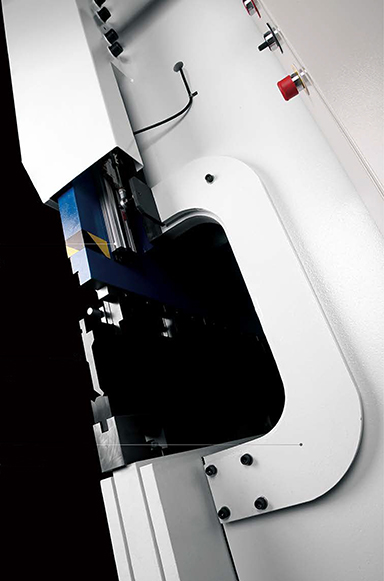

| Italian GV Grating Ruler Using Italian GV grating ruler to ensure higher bending accuracy Throat deformation compensation mechanism The grating ruler is installed on the C-shaped plate at the throat position, so that it can compensate for the deformation of the throat slightly under high pressure, ensuring higher bending accuracy |

Quick Clamping Device For Molds Adopting a high-precision mold quick clamping device, with a one click release design and an anti drop structure, the mold will not fall off after being released, making mold replacement safer CNC bending mold Forged alloy steel upper mold The upper mold is made of forged alloy steel as raw material for CNC machining, and the surface can be treated with blackening and rust prevention, and can be customized in sections Same core CNC lower mold The lower mold adopts a same core design, with high conversion efficiency between mold openings Customizable dual core 4-port design |  |

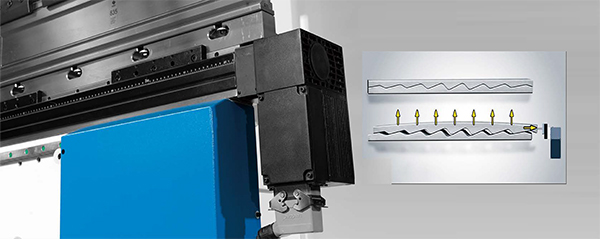

| CNC Deflection Compensation Structure With deflection compensation structure, the Press brake has higher working accuracy and more accurate angle There are two types of deflection compensation: mechanical and hydraulic, each with its own characteristics. Our compa- ny's mechanical deflection compensation Mechanical Deflection Compensation Made of high-strength steel with inclined blocks or nonlinear wave structures inside |

| 63T25 | 100T32 | 100T40 | 125T32 | 125T40 | 160T32 | 160T40 | 200T32 | 200T40 | ||

| Capacity | KN | 630 | 1000 | 1000 | 1250 | 1250 | 1600 | 1600 | 2000 | 2000 |

| Table Length | mm | 2500 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 |

| Between Columns | mm | 2100 | 2600 | 3100 | 2600 | 3100 | 2600 | 3100 | 2600 | 3100 |

| Daylight Opening | mm | 420 | 460 | 460 | 460 | 460 | 460 | 460 | 460 | 460 |

| Ram Stroke | mm | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Throat Depth | mm | 320 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Approach Speed | mm/s | 180 | 180 | 180 | 180 | 180 | 160 | 160 | 150 | 150 |

| Working Speed | mm/s | 12 | 10 | 10 | 10 | 10 | 9 | 9 | 9 | 9 |

| Return Speed | mm/s | 170 | 160 | 160 | 160 | 150 | 150 | 140 | 140 | 130 |

| Main Motor Power | kw | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 |

| X axes stroke | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| X axes speed | mm/s | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| R axes stroke | mm | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| R axes speed | mm/s | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Cybelc Touch 8 8 "color LCD display, touch screen, icon recognition function Easy single bending processing on the "EasyBend" pageFully efficient bending programming to meet the needs of large-scale production and processing Automatically calculate bending angle, main pressure, and deflection compensation Automatic calculation of bending data Automatic calculation of pressure and tension compensation; Automatic calculation of upper mold depth Angle, rear stopper correction |  | Cybelc Touch 12 12 "color LCD display, touch screen, icon recognition function Easy single bending processing on the "EasyBend" pageFully efficient bending programming to meet the needs of large-scale production and processing Automatically calculate bending angle, main pressure, and deflection compensation Automatic calculation of bending data Automatic calculation of pressure and tension compensation; Automatic calculation of upper mold depth Angle, rear material correction, 2D graphic programming Automatically simulate bending steps and provide the optimal bending solution (option) |

| Cybelc Touch 15 15 "color LCD display, touch screen, icon recognition function Easy single bending processing on the "EasyBend" pageFully efficient bending programming to meet the needs of large-scale production and processing Automatically calculate bending angle, main pressure, and deflection compensation Automatic calculation of bending data Automatic calculation of pressure and tension compensation; Automatic calculation of upper mold depth Angle, rear material correction, 2D graphic programming Automatically simulate bending steps and provide the optimal bending solution (option) |  | Cybelc Touch VT19 19 "color LCD display, touch screen, icon recognition function Easy single bending processing on the "EasyBend" page Fully efficient bending programming to meet the needs of large-scale production and processing Automatically calculate bending angle, main pressure, and deflection compensation Automatic calculation of bending data Automatic calculation of pressure and tension compensation; Automatic calculation of upper mold depth Angle, rear material correction, 2D graphic programming, 3D preview Automatically simulate bending steps and provide the optimal bending solution |

| DELEM DA53T TIntegrated touch screen electrohydraulic Shortcut Key Touch Navigation10.1 "High resolution true color TFT display screen Up to 4 axis control (Y1:Y2+2 auxiliary axes) Deflection compensation control With mold/material/stand up library Support servo or variable frequency control Advanced Y-axis control algorithm, which can control both Closed loop valve, can also control open loop valve Network dual machine linkage (optional) USB peripheral interface Profile-53TL offline programming software |  | DELEM DA58T Integrated touch screen 2D touch graphics programming15 "high-resolution TFT direct color display Bending process caliculation Disturbancie compensation control Servo and frequiency converter control mode The Y-axis control method mentioned earlier can be used to control Closed loop valve, can also control open loop valve USB interface |

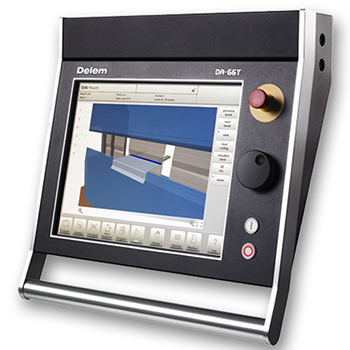

| DELEM DA66T Integrated touch screen electrohydraulic Shortcut Key Touch Navigation10.1 "High resolution true color TFT display screen Up to 4 axis control (Y1.Y2+2 auxiliary axes) Deflection compensation control With mold/material/stand up library Support servo or variable frequency control Advanced Y-axis control algorithm, which can control both Closed loop valve, can aiso control open loop valve Network dual machine linkage (optional) USB peripheral interface Profile-53TL offline programming software | ||

| 1. Wall panels; 2. fuel tanks; 3. Slider; 4. Synchronization blocks; 5. Pressure block; 6. Deflection compensation workbench; 7. Main oil cylinder; 8. Main motor; 9. Oil pump; 10. Rear stopper; 11. Electric control box; 12. CNC system; 13. Control station; 14. Cylinder cover; 15. Safety signs; 16. Prevention of accidental injury standard. |

Related Products

AHXISIM CNC Tandem Press Brake

AHXISIM CNC Tandem Press Brake

AHXISIM 6+1 Axis DA66T CNC Press Brake

AHXISIM 6+1 Axis DA66T CNC Press Brake

NC Press Brake

NC Press Brake

Oil Electric Hybrid Drive Press Brake

Oil Electric Hybrid Drive Press Brake

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 19955505001

Email: info@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY