AHXISIM 6+1 Axis DA66T CNC Press Brake

CNC Press Brake For Quiet Operation With Large Daylight & Stroke

PARAMETER

AHXISIM 6+1 Axis DA66T CNC Press Brake

AHXISIM Hybrid servo CNC press brake Based on proven design it has increased working speeds, stroke, daylight & pressing capacities. With advanced motion technologies and impressively quiet with the most flexible features and options, it is the ultimate in creating complex parts

Energy saving, environmentally friendly, and efficient CNC hybrid press brake

Unique fully closed-loop servo hydraulic energy-saving system, with significant economic benefits

Adopting mechanical compensation structure to ensure perfect bending quality

The rear gear adopts imported internationally renowned brand digital AC servo motor control

Large lead precision ball screw transmission, linear guide rail guidance

The AHXISIM Hybrid Servo ECO system is an innovative servo drive for press brakes, and thanks to servo motor, we can precisely control the movement of the ram using a minimum amount of oil and energy

Hybrid Servo ECO Function

AHXISIM New Hybrid Servo ECO Function.

AHXISIM promotes a friendly environmental policy, and as such all our equipment features the Hybrid ECO Function. Our hybrid servo-drive positioning system provides accuracy at any position.

Brand hydraulic valve group

Ensure precise pressure control, synchronize left and right cylinder positions, and have a long service life

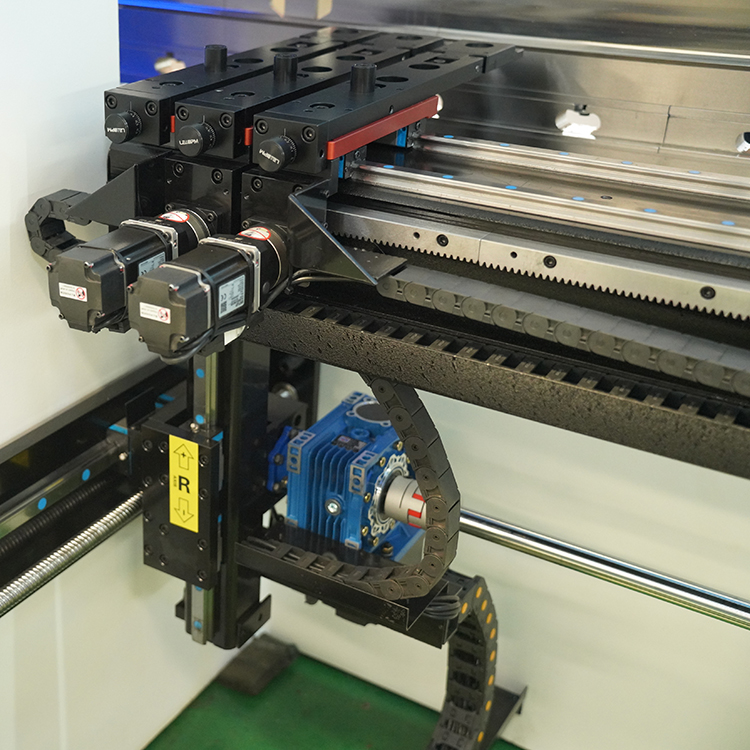

Press Brake 4-Axis CNC BackGauge With X, R, Z1, Z2-Axis

Ball screws and linear guide on X, R-axis.

Precision belts and YYC rack on axes Z1‐Z2.

Fingers with double stop and micrometric adjustment.

Mechanical accuracy ± 0.03 mm.

Axes Z1‐Z2 speed 1000 mm/s.

Axis X speed 500 mm/s.

SPA Thin supports system in the fingers.

Load capacity – 30 kg per support.

Accurate and fast rear blocking material

The X-axis adopts ball screw and linear guide transmission

High positioning accuracy and long service life

Widening and lengthening customized gear finger

Support frame for double linear guide rail

2D graphical touch screen programming mode

17" high resolution colour TFT

Full Windows application suite

Delem Modusys compatibility (module scalability and adaptivity)

USB, peripheral interfacing

User specific application support within the control's multitasking environment

Sensor bending & correction interface Profile-TL offline software

Hydraulic Clamping System:

The Standard Tooling System has become market leader for precision, quality and flexibility for the AHXISIM hydraulic press brakes for sale

Advantage:

Long service life: >10 years

Quick clamping for style tooling

Simple push-button loading

Fast and safe tool changes: Reduce 80% time

High-precision bending angle and flange edge

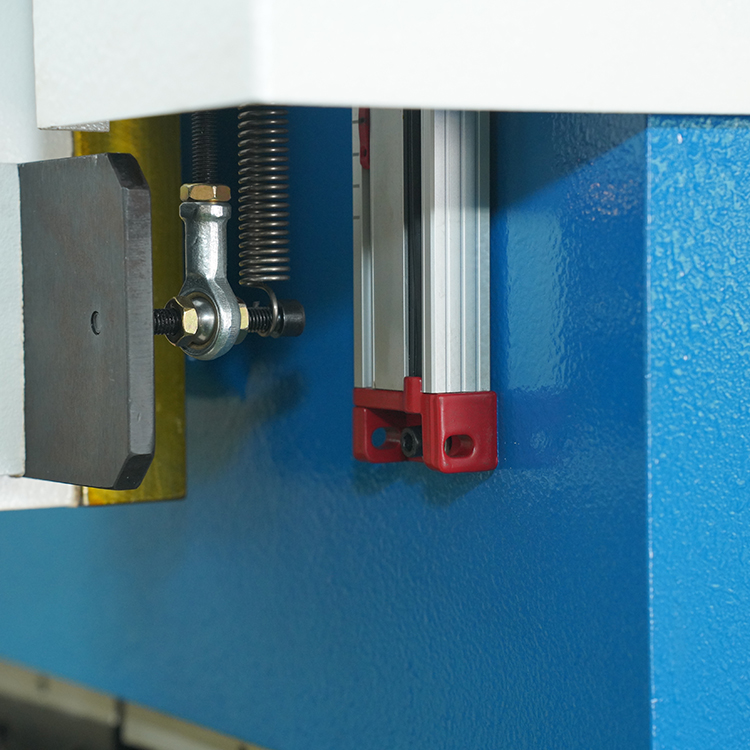

Equipped with a deflection compensation structure, the bending machine operates with higher precision and more accurate angles

Made of high-strength steel with inclined blocks or nonlinear wave structures inside

The AHXISIM CNC Crowning system enables theuser to offset deformations of the beam while bending. thus, the angle iskeeping constant along the entire plate length.

Advantage:

Easy reversibility of tools because of symmetrical adaption

Hand crank with digital readout or CNC electric drive connected direct to the machine

Hardened to 28–32 HRC which makes it substantially tougher than the competition

Micro crowning every 200mm

T & Y adjustable 0–0.76mm (0–0.030")

Adopting Italian GV grating ruler to ensure higher bending accuracy and safety

Safety laser protection provide superior optical protection while maintaining the highest level of productivity and performance for CNC press brake.

Related Products

Single Cylinder Series 120KN 600mm Full Electric Press Brake

Single Cylinder Series 120KN 600mm Full Electric Press Brake

Oil Electric Hybrid Drive Press Brake

Oil Electric Hybrid Drive Press Brake

AHXISIM CNC Tandem Press Brake

AHXISIM CNC Tandem Press Brake

Hydraulic CNC Sheet Metal Press Brake

Hydraulic CNC Sheet Metal Press Brake

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 19955505001

Email: info@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY