Comparison between heavy-duty panel bender and standard model

Dec. 19, 2024

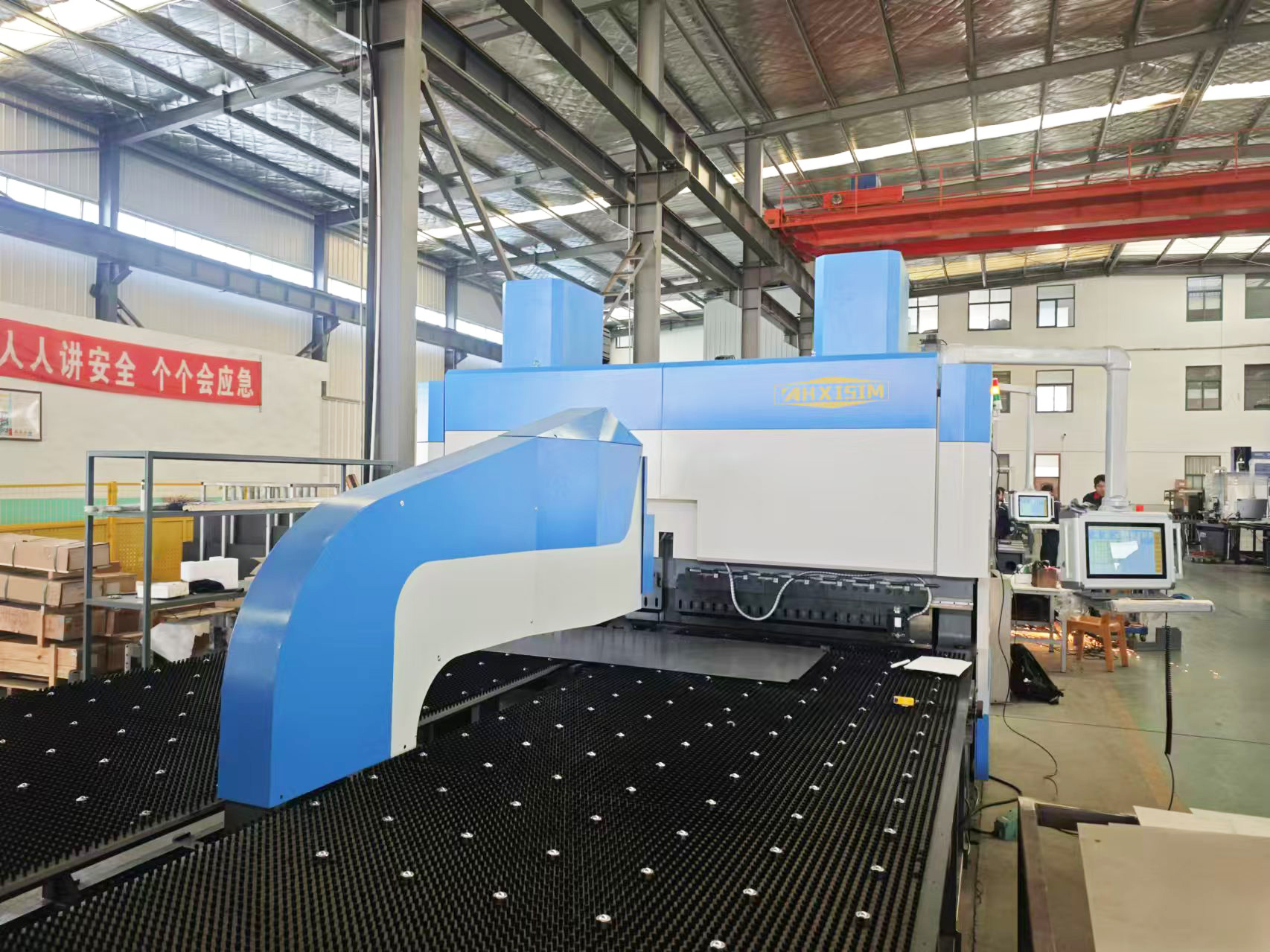

Today, let's take a look at the products of the well-known Chinese brand Panel Bender, AHXISIM Intelligent.

It usually has a high bending speed, a high degree of automation, can quickly complete the bending operation, greatly reducing the cycle time of multi-sided and multi-pass bending, and has obvious speed advantages in the processing of complex work-pieces. For example, the multi-sided Panel Bender was once popular in the industry and followed, showing efficient bending capabilities.

The technical requirements for customer operators are generally low. They only need to undergo professional training to become familiar with the operation and programming of the equipment. Once they are proficient, they can efficiently perform the bending processing of complex work-pieces.

In terms of the system, Taiwan CYNTEC uses advanced technology and precise control systems, which perform well in positioning accuracy and can ensure the accuracy and stability of bending, so that the processed products have high consistency, which is suitable for production with high product precision requirements.

High degree of automation, with advanced automation technology and intelligent control system, can realize highly automated production process, from work-piece loading to bending processing, and then to unloading, the whole process is smooth and efficient, reducing manual intervention, improving production efficiency and quality stability, and reserved for cooperation with other sheet metal equipment, sheet metal production line intelligent interface, etc.

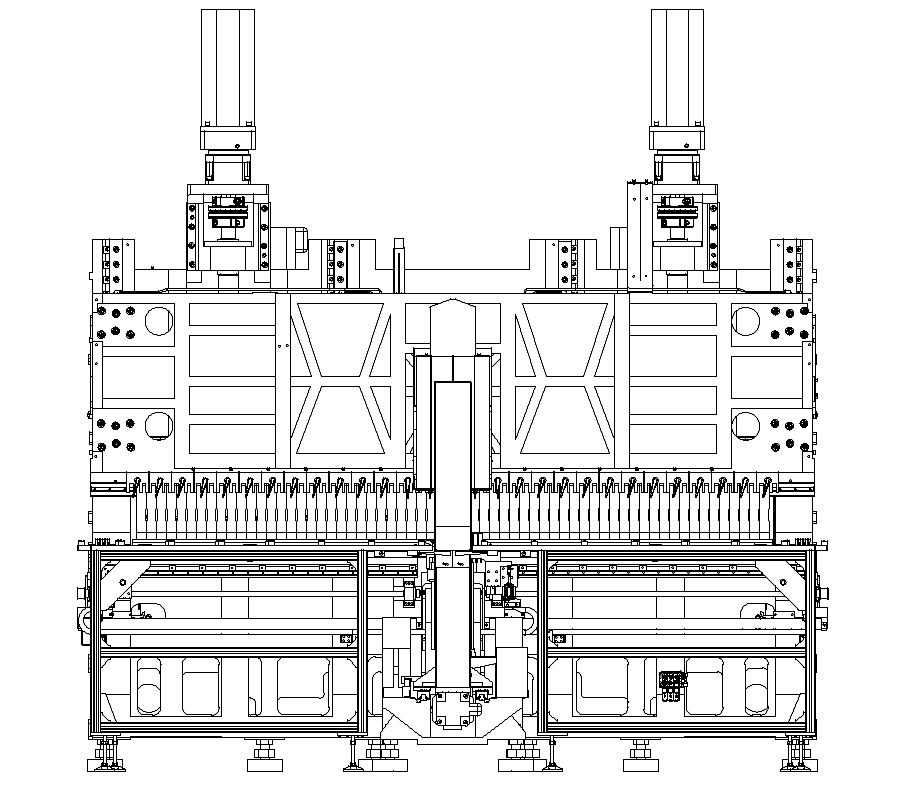

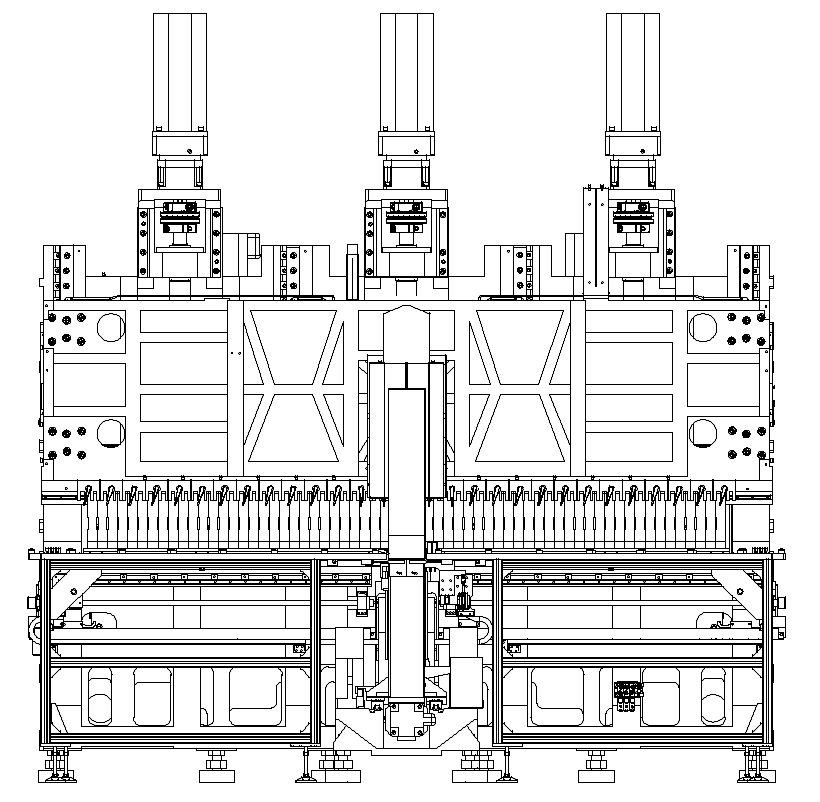

AHXISIM Intelligence, in the heavy-duty Panel Bender series compared with peers, the W axis uses a three-axis form, with greater clamping force and more uniform pressure distribution, ensuring improved machine stability and bending accuracy angle.

Comparison of changes in energy efficiency and speed of corresponding parameters:

1. W-axis screw 8020, XZ-axis screw 6320, (standard type, W-axis screw 6320, XZ screw 6320),

2. Normal bending work-piece has no effect. When switching between positive and negative bending, such as step difference, the step difference length will be longer.

3. The motor power is increased by 30% for thinner plate type.

4. Maximum bending thickness, cold plate 2.8, 304 stainless steel 1.5, aluminum plate 3.5,

5. The speed is slowed down by 25% for thinner plate type.

6. The mold uses thickened mold, which has higher strength and longer service life. The mold service life is 2 million times for iron plate, 1 million times for stainless steel plate, and 2.5 million times for aluminum plate.

7. The guide rail of 2.5-meter model is 55, and the guide rail of 2-meter model is 45.

8. The fuselage of heavy-duty machine is reinforced and has high strength.

Standard Type

Heavy-duty Type

In general, AHXISIM Panel Bender has a profound background in technology and brand history, which is suitable for enterprises with high requirements for processing accuracy and complex processes. It has advantages in automation, ease of use and cost, and is suitable for enterprises pursuing efficient production and reducing labor costs.

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 19955505001

Email: info@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY