A Guide to Panel Bender Machine Maintenance and Operation

Nov. 08, 2024

Panel bender machines are specialized equipment used to bend large, flat sheets of metal into precise angles and shapes, commonly used in industries like automotive, HVAC, and metal fabrication. These machines are designed for high-speed, accurate bending of sheet metal panels and are essential for producing parts like panels, covers, and housings. Proper maintenance and correct operation are key to ensuring these machines perform optimally. In this guide, we’ll cover everything you need to know about panel bender machine maintenance and operation to keep your machine running smoothly and efficiently.

A panel bender machine is designed to bend large sheets of metal into various shapes with high precision. Unlike traditional press brakes, panel benders use a set of specialized tools and advanced automation systems to bend the metal without requiring extensive manual intervention. These machines are highly automated, making them ideal for bending high volumes of sheet metal quickly and accurately, while maintaining a consistent product quality.

Panel benders can handle materials such as aluminum, stainless steel, and mild steel. The process involves clamping the sheet metal between tooling and then bending it incrementally, making them especially effective for creating parts that require complex bends or multiple angle changes.

Just like any high-precision equipment, panel bender machines need regular maintenance to ensure smooth operation and avoid costly downtime. Proper maintenance can also help improve machine longevity and ensure high-quality output. Below are some essential maintenance tasks to keep your panel bender machine in top condition.

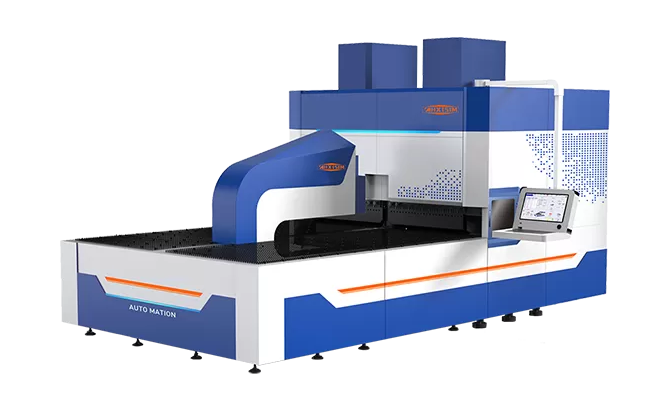

Sheet Metal Flexible Panel Bender Press Arm Series

Daily maintenance focuses on checking the machine’s condition before operation and ensuring that everything is running smoothly:

Clean the Machine: Remove any metal shavings, dust, or debris from the machine, particularly around the tooling, bending area, and electrical components. Keeping the machine clean ensures smoother operation and minimizes the risk of contamination or damage.

Inspect Hydraulic System: For machines with hydraulic systems, check the fluid levels and look for any leaks. Low or dirty hydraulic fluid can reduce the machine's performance and cause damage over time.

Lubricate Moving Parts: Ensure that all moving parts, including the clamping and bending arms, are well-lubricated to reduce friction and wear. Regular lubrication prevents premature wear and keeps the machine running smoothly.

Check Electrical Connections: Inspect the electrical system for any loose connections or signs of wear. Tighten or repair any loose wires to prevent electrical issues.

Weekly maintenance involves more in-depth checks to ensure the machine is operating at its best:

Inspect Tooling and Dies: Check the condition of the bending dies and tools. Worn dies can affect the accuracy of the bends and lead to defects in finished products. Ensure tools are properly aligned and replace any that show significant wear.

Check for Hydraulic Leaks: Look for signs of leakage in the hydraulic system. Any leaks in hoses, valves, or cylinders should be addressed promptly to avoid loss of hydraulic pressure.

Verify the Backgauge System: Check the backgauge system, which helps position the sheet metal. Ensure it moves smoothly and accurately to avoid misalignment during bending. Calibration of the backgauge is critical for consistent results.

Monthly maintenance typically involves a more thorough inspection of the machine's components:

Inspect the Machine Frame: Check for any cracks, deformation, or damage to the machine’s frame. A stable and rigid frame is crucial for maintaining accurate bends.

Clean the Hydraulic Tank: If your panel bender uses hydraulic systems, clean and replace the hydraulic fluid. Contaminated fluid can impair the performance of hydraulic components.

Check the Control System: Test the machine’s CNC control system for accuracy. Ensure the system is functioning correctly and that all programs and settings are optimized.

Application Scenario of Panel Bender

Annual maintenance is a comprehensive check-up that should be performed by a trained technician to ensure the machine is in peak condition:

Full Calibration: Perform a full calibration of the machine to ensure it is producing accurate bends. Any minor misalignments should be corrected during this process.

Check All Bearings: Inspect the bearings on moving parts for any wear or damage. Replacing worn bearings can prevent unnecessary machine vibrations and ensure smoother operation.

Replace Worn Components: Any components that have shown significant wear or damage throughout the year should be replaced to avoid future issues and improve machine longevity.

Proper operation is essential to achieve precise results and ensure the machine’s longevity. Here’s a step-by-step guide for operating a panel bender machine safely and effectively:

Before starting the bending process, ensure the machine is properly set up:

Choose the Correct Tooling: Select the appropriate dies and tooling for the material and required bend. Different materials and thicknesses may require different dies or tooling setups.

Load the Material Properly: Place the sheet metal into the machine’s clamping system, making sure it is aligned properly. Misalignment can result in inaccurate bends and waste material.

Input Bend Parameters: Enter the required bend angle, material thickness, and other specifications into the CNC control system. Double-check all parameters to ensure accuracy.

Once the machine is set up, proceed with the bending process:

Start the Bending Process: Activate the machine to begin the bending process. The panel bender will automatically clamp the sheet and start applying pressure to form the bends.

Monitor the Bending: Observe the bending process to ensure the material is being shaped as expected. Ensure there is no excessive vibration or any issues with alignment.

Adjust Parameters if Needed: If the bend is not forming correctly, adjust the machine settings or reposition the sheet metal to correct the issue.

After the bending process, carefully inspect the finished part for accuracy:

Check for the Correct Bend Angle: Use a protractor or laser measurement tool to verify that the bend angle is accurate. If it is not within tolerance, recalibrate the machine and try again.

Inspect for Surface Defects: Examine the surface of the material for any signs of damage, cracks, or imperfections. If defects are present, inspect the tooling and material handling process to identify the cause.

Ensure Proper Dimensions: Measure the overall dimensions of the part to ensure they meet the required specifications.

Even with regular maintenance, panel bender machines can encounter issues. Here are some common problems and their solutions:

Inaccurate Bends: This could be due to incorrect tooling, misalignment of the sheet metal, or issues with the CNC system. Ensure the tooling is correctly selected and the backgauge system is properly calibrated.

Hydraulic Leaks: Leaks in the hydraulic system can lead to loss of pressure and poor machine performance. Inspect hoses and seals for damage and replace any leaking parts.

Tooling Wear: Over time, tooling can wear down and affect bending accuracy. Inspect dies and replace them when they show signs of wear or damage.

Panel bender machines are crucial for achieving precise, high-quality bends in sheet metal, and maintaining them is essential for optimal performance. By following a consistent maintenance schedule and operating the machine properly, you can ensure that your panel bender machine produces accurate parts while minimizing downtime and maintenance costs. With regular care and attention, your machine will continue to provide reliable service for years to come.

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 19955505001

Email: info@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY