PARAMETER

Laser cutting machine is a device that uses laser technology to cut metal materials. Its characteristics and selling points are as follows:

High precision: The laser cutting machine uses a laser beam as the cutting tool, which can achieve very fine cutting with smooth cutting edges and no need for secondary processing.

High speed: The laser cutting machine has a fast cutting speed, which can quickly complete batch cutting tasks and improve production efficiency.

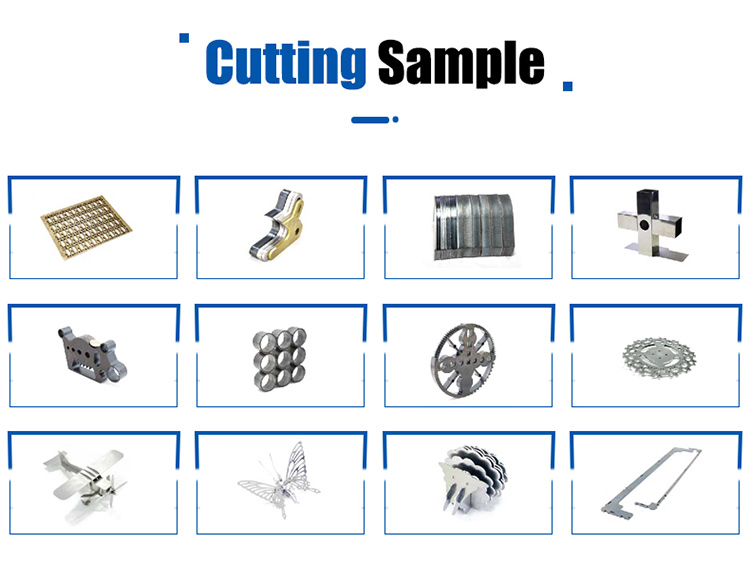

Flexibility: Laser cutting machines are suitable for cutting various metal materials, such as steel, aluminum alloys, etc., and can achieve complex shape cutting to meet different processing needs.

Non contact cutting: Laser cutting is a non-contact cutting technology that does not require any force to be applied to the workpiece, does not produce deformation or deformation, and maintains the original performance and appearance of the material.

Material saving: The laser cutting machine adopts a small blade for cutting, with narrow cutting seams, saving materials and reducing production costs.

High degree of automation: Laser cutting machines are equipped with advanced CNC systems, which can achieve automated cutting, improve production efficiency and ease of operation.

By emphasizing the above characteristics and selling points, the high precision, high speed, flexibility, and automation level of laser cutting machines can be highlighted, attracting customers to purchase and use them. At the same time, it can also emphasize the advantages of non-contact cutting and material saving of laser cutting technology, as well as its applicability to various metal materials, to increase its market competitiveness.

The laser cutting machine is a laser that is emitted from a laser and is focused into a high power density laser beam through an optical circuit system. The laser beam irradiates the surface of the workpiece, causing the workpiece to reach the melting or boiling point, while a high-pressure gas coaxial with the beam blows away the molten or vaporised metal.

As the beam moves relative to the position of the workpiece, it eventually creates a slit in the material, which results in a cut.

Laser cutting process is an invisible beam instead of the traditional mechanical knife, with high precision, fast cutting, not limited to the cutting pattern limitations, automatic layout to save materials, smooth kerf, low processing costs, etc., will gradually improve or replace in the traditional metal cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece, and will not cause scratches on the surface of the workpiece during the work; the laser cutting speed is fast, the kerf is smooth and even, and generally does not require subsequent processing; the cutting heat-affected zone is small, the plate deformation is small, and the cutting slit is narrow (0.1mm~0.3mm); there is no mechanical stress on the kerf, and there is no shear burr; the processing precision is high, and the repeatability is good, and it does not damage the surface of the material; the numerical control programming, it can process Arbitrary planogram, can cut the whole plate with a large width, no need to open the mould, economic and time-saving.

Independently developed cutting head

Independently developed operating system

Intelligent number chuck

Core technology

| Product Model | XSM-3015-J-220-6M | XSM-6015-J-220-6M | XSM-4020-J-220-6M | XSM-6020-J-220-6M |

| Working Area | 3000*1500mm | 6000*1500mm | 4000*2000mm | 6000*2000mm |

| Laser Power | 1000W,1500W,2000W,3000W,4000W | |||

| Positioning Accuracy | +-0.03mm/m | |||

| Repeated Positioning Accuracy | +-0.02mm | |||

| Voltage | 380VAC+-10%/50Hz | |||

| Cutting Pipe Performance | XSM-3015GT | XSM-6015GT | XSM-4020GT | XSM-6020GT |

| Maximum Moving Speed | 120m/min | |||

| Maximum Cutting Speed | 60m/min | |||

| Drive System | High precision gear and rack+high precision linear guide rail | |||

| Plate Cutting Performance | XSM-3015GT | XSM-6015GT | XSM-4020GT | XSM-6020GT |

| Pipe Dimension | Circular tube 20-200mm/Square tube 20*20mm-150*150mm | |||

| Processing Tube Type | Round tubes,rectangular tubes,eliptical tubes,U tubes etc. | |||

| Maximum Pipe Length | 3000-15000mm | |||

| Fast Moving Speed | 30m/min | |||

| Rotational Speed | 150r/min | |||

| Drive System | High precision gear and rack+high precision linear guide rail | |||

| |||||

|  | ||||

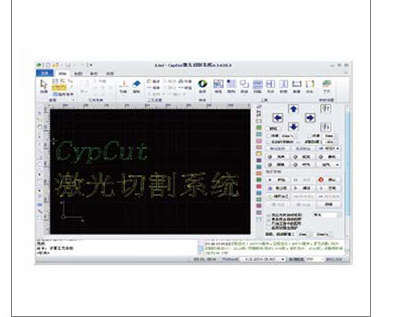

Laser Head Brand The best cutting effect of different thickness metals can be achieved by adjusting the focus automatically in the cutting process | Laser Cutting System CypCut It is stable and reliable,easy,to deploy,easy to debug,safe in production,rich in function and excellent in performance | ||||

|  |  | |||

| Brand Rack And Pinion | Imported Linear Guide | Japan Imported Reducer | |||

|  |  | |||

| Steel Sheet Bed | Imported Servo Motor | Brand Laser Source | |||

|  | ||||

| Industrial Chiller | Laser Generator | ||||

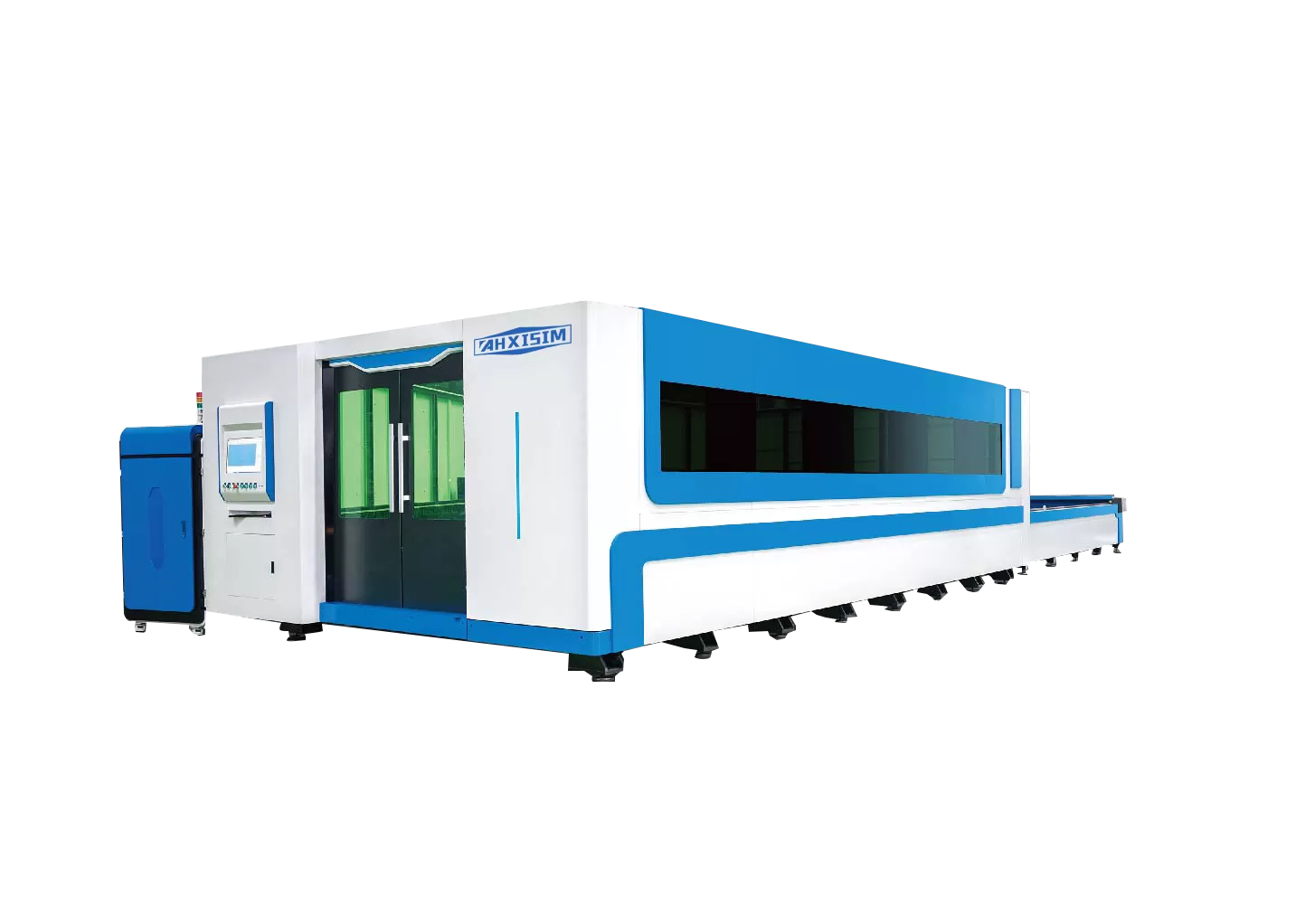

1. Strong ventilation system,environmental protection and no pollution.

2. The worktable is driven by double motors,with stable exchange and high speed;

The slag cleaning table is more convenient and independent without mutual influence.

3. Fully protected closed design.

AHXISIM Laser

AHXISIM Laser

Anhui Hisman Intelligent Equipment Manufacturing Co., Ltd. was established in 2013. It is a national high-tech enterprise that integrates the research and development, production, and sales of metal forming intelligent equipment, committed to providing metal forming intelligent equipment solutions for global users.

Technology Study

Technology Study

AHXISIM Laser has a professional independent core R&D team, accounting for over 12% of the company's total employees. The company has established long-term cooperative relationships with multiple universities and conducts talent cultivation. The company relies on mature software development and controller development advantages, comprehensively mastering core technologies such as CNC systems, precision cutting heads, and high-speed transmission systems. The equipment processes products with higher accuracy, smoother cutting edges, faster speed, and higher production capacity.

Customer Service

Customer Service

AHXISIM laser rapid response customer service team accounts for over 20% of the company's total employees, including professional teams such as pre-sales service, sales service, after-sales service, customer training, etc., covering technical process consulting, visits and incoming material reception, customer on-site visit planning, and installation and debugging. Provide free training for customer personnel, equipment maintenance and repair, and provide a comprehensive and fast response service of 7*24 hours.

Free Training

Free Training

To ensure that customers can use their devices efficiently and safely, AHXISIM Laser will provide free and complete equipment operation training. Before using the equipment, the customer needs to dispatch the equipment operator to the AHXISIM laser training center to receive standardized training that matches the purchased model. Finally, after strict system theoretical assessment and on-site practical operation assessment, a certificate will be issued after passing the assessment, and the employee will be certified to work, effectively ensuring the safety of the equipment and operators.

Related Products

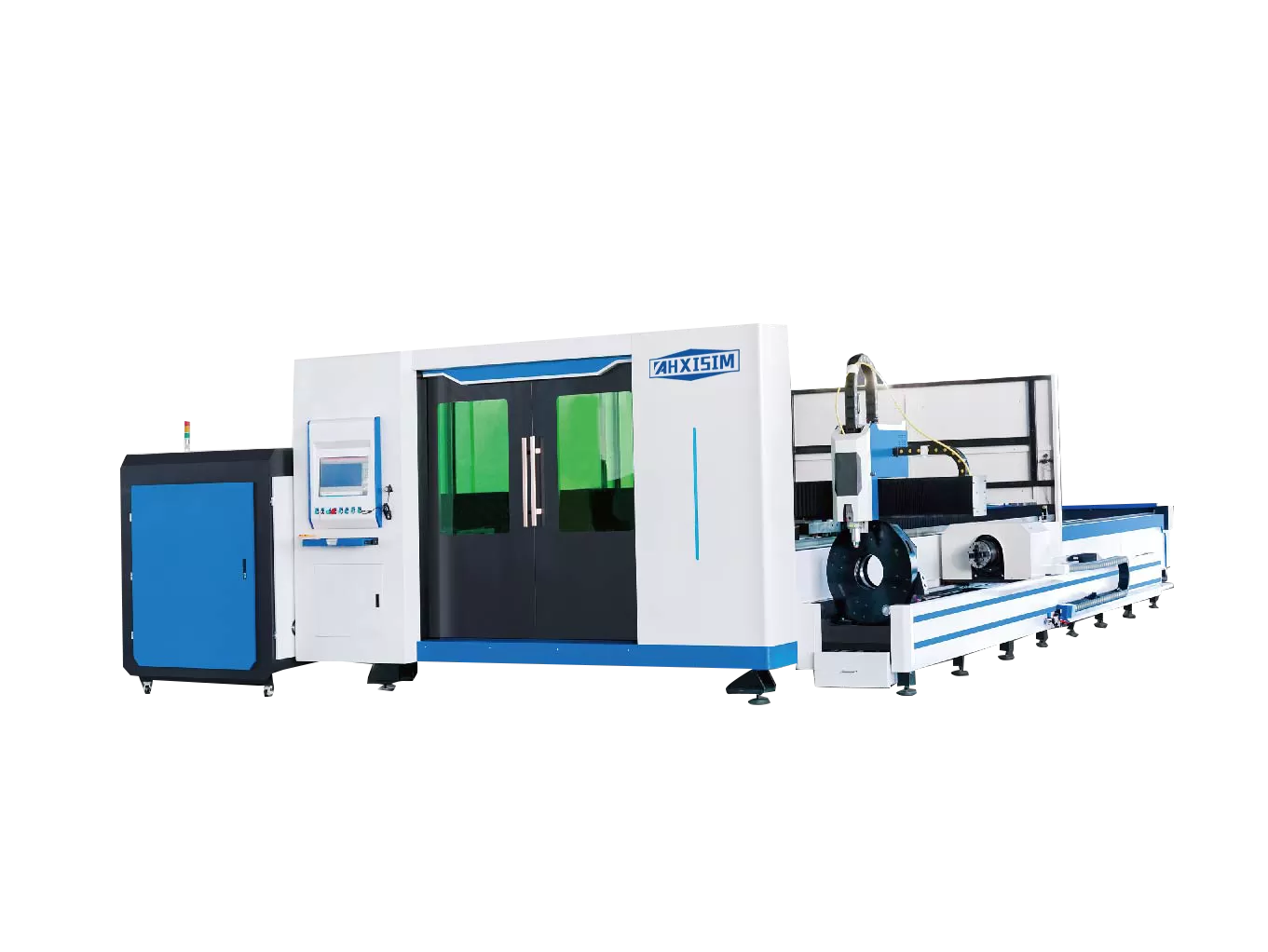

Exchange Table Plate And Tube Fiber Laser Cutting Machine Enclosed

Exchange Table Plate And Tube Fiber Laser Cutting Machine Enclosed

Enclosed Metal Sheet Fiber Laser Cutting Machine

Enclosed Metal Sheet Fiber Laser Cutting Machine

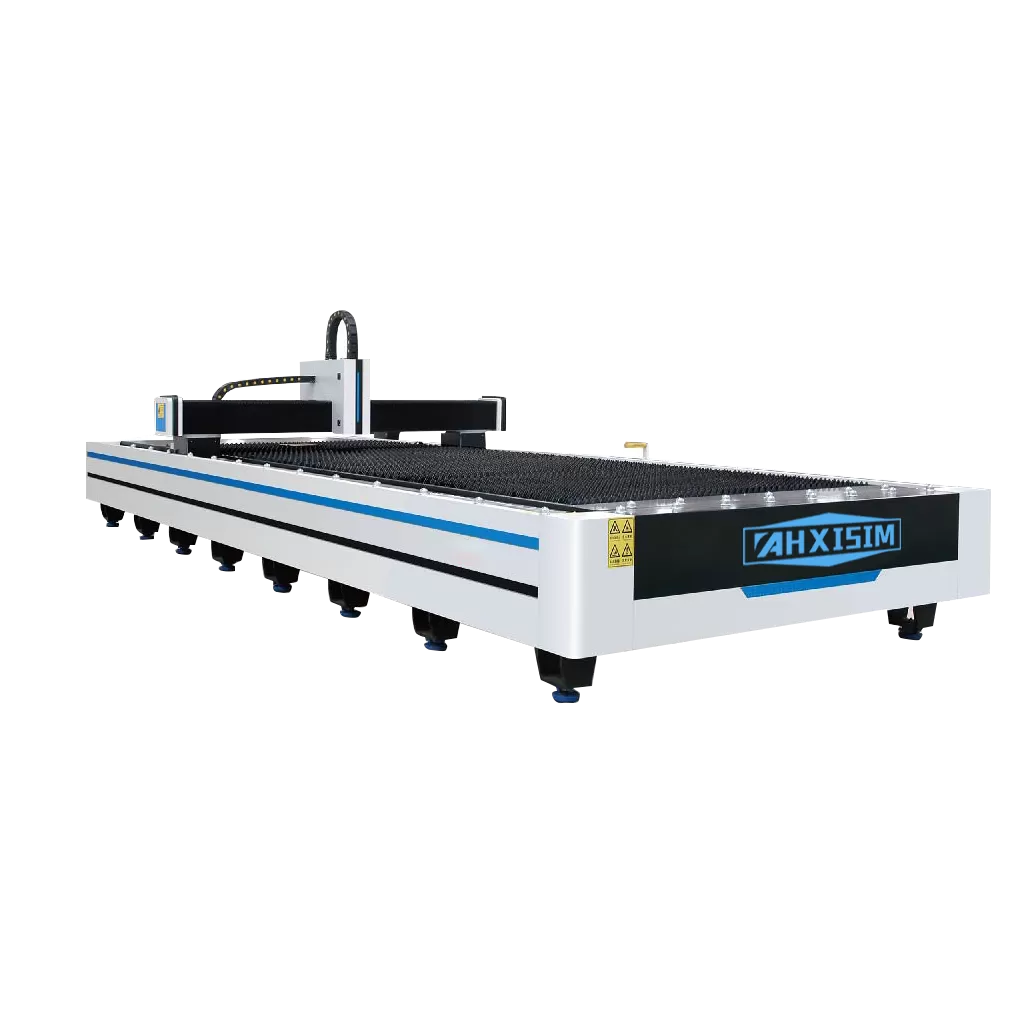

Metal Fiber Laser Cutting Machine

Metal Fiber Laser Cutting Machine

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 19955505001

Email: info@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY